Home /

Environmental, Social,

Governance

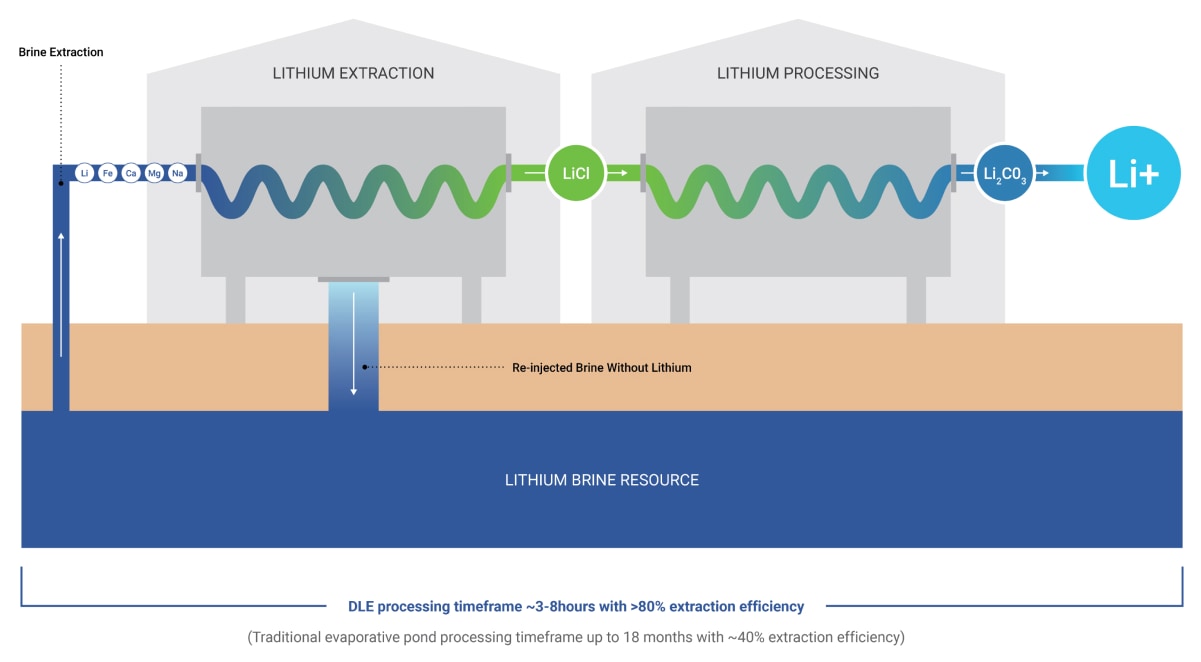

Using cleaner technology to produce sustainable lithium to meet global demand

The historical method of processing lithium brine is to use evaporation ponds – this requires a large land ‘footprint’ and can take up to 18 months to harvest the lithium. Recently, a process called Direct Lithium Extraction (DLE) has shown that lithium can be processed in a more time-efficient and environmentally responsible way.

There are approx. 9 DLE methods being trialled throughout South America.

Basic overview of Direct Lithium Extraction (DLE) process

DLE has several potential benefits

- Reducing the footprint of evaporation ponds

- Decreasing production times compared with conventional brine operation

- Increasing recoveries from ~40% to over 80%

XTC Lithium’s proposed DLE pathway

- Initial phase will be a R&D partnership, followed by a MoU

- To be determined by drilling programme in Argentina and sample availability

- Entering into a formal collaboration agreement by Q3 2022